Boost Durability: Aftermarket Construction Parts Option

Wiki Article

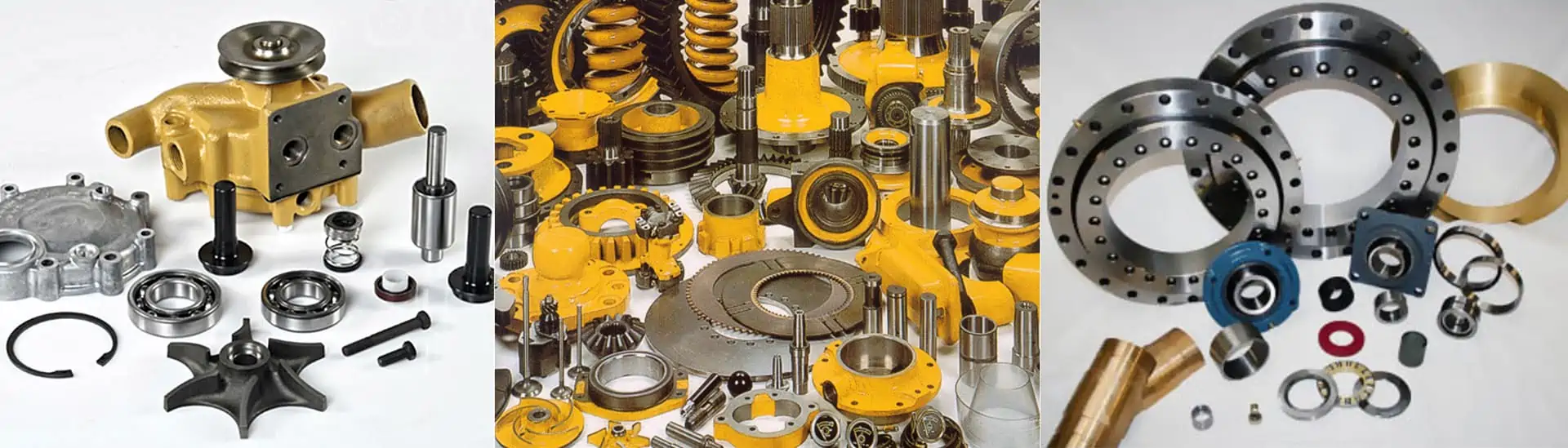

Boost Performance With Costs Aftermarket Building Components for Heavy Machinery

Benefits of Premium Aftermarket Parts

When taking into consideration hefty machinery upkeep, going with costs aftermarket parts uses substantial advantages in regards to cost-effectiveness and performance dependability. Costs aftermarket components are developed to fulfill or exceed the original devices producer (OEM) specs, guaranteeing a high degree of quality and compatibility. These components are frequently much more affordable than their OEM equivalents, making them a cost-efficient remedy for companies looking to keep their hefty machinery without endangering on performance.Construction sites and industrial setups can be rough settings, placing tremendous stress on equipment components. By selecting premium aftermarket components, businesses can lessen downtime, decrease maintenance prices, and guarantee that their equipment runs at peak efficiency.

Enhancing Machinery Efficiency

One of the substantial advantages of utilizing costs aftermarket components for heavy equipment upkeep is the enhancement they bring to equipment performance in demanding operational settings. In addition, premium aftermarket components can assist maximize fuel consumption, minimize downtime for repair work, and reduce the threat of unanticipated malfunctions, ultimately leading to a smoother and a lot more effective procedure of hefty machinery in various building and construction and commercial settings. Investing in costs aftermarket components is a critical selection for business looking to enhance the efficiency and long life of their heavy machinery fleet.Economical Solutions for Upgrades

Executing economical services for upgrades in heavy machinery maintenance can significantly influence functional efficiency and general efficiency. When considering upgrades, it's vital to prioritize financial investments that supply a balance between quality and cost-effectiveness. One cost-effective service is going with premium aftermarket components that supply similar efficiency to original tools maker (OEM) components but at a reduced price point. These aftermarket parts undergo rigorous testing to guarantee they fulfill industry requirements and specifications, making them a reputable choice for machinery upgrades.Normal maintenance and timely upgrades can help stop pricey downtime and expand the lifespan of hefty equipment. An additional affordable strategy is to invest in modern technology upgrades, such as telematics systems, which can enhance equipment surveillance and efficiency optimization - aftermarket construction parts. These systems make it possible for real-time monitoring of maker health and wellness metrics, enabling for positive maintenance and lessening the risk of unforeseen failures

Enhancing Equipment Durability

Enhancing the toughness of hefty machinery is critical for making best use of functional performance and lowering general maintenance costs. Raising machinery durability entails executing aggressive actions to expand the lifespan of tools. Normal upkeep timetables, consisting of oil adjustments, filter replacements, and assessments, are vital to stop early wear and identify prospective concerns before they intensify. Using premium aftermarket components particularly created for hefty machinery can additionally add to prolonging the lifespan of devices. These parts are usually much more trustworthy and long lasting than basic OEM elements, using increased durability to harsh working problems. Furthermore, purchasing innovative modern technologies such as telematics systems can supply real-time information on machine performance, making it possible for drivers to resolve maintenance needs quickly and successfully. By focusing on equipment durability via a combination of precautionary upkeep techniques and quality aftermarket components, construction click here to read firms can enhance the effectiveness and cost-effectiveness of their procedures while minimizing downtime because of unforeseen break downs.Optimizing Equipment Performance

To make sure the peak performance of hefty equipment, optimizing equipment performance is essential for construction companies aiming to make best use of functional effectiveness and minimize downtime. One key facet of optimizing machinery functionality is performing routine upkeep checks to identify and address any type of possible problems before they intensify. Executing a preventative upkeep timetable can help in spotting worn-out parts or components that may hinder the this post equipment's efficiency. Furthermore, making use of sophisticated innovation systems and software application for keeping track of devices health and wellness and efficiency metrics can offer real-time data understandings, making it possible for positive maintenance interventions.Including performance monitoring devices can assist in evaluating equipment usage patterns and identifying areas for improvement or change to optimize performance. By focusing on equipment functionality optimization, construction firms can boost performance, extend equipment life-span, and ultimately accomplish higher returns on their hefty machinery investments.

Verdict

When considering hefty equipment upkeep, opting for costs aftermarket parts uses substantial benefits in terms of cost-effectiveness and performance dependability.One of the substantial benefits of using costs aftermarket parts for hefty equipment maintenance is the improvement they bring to machinery performance in requiring operational settings.To ensure the peak performance of hefty equipment, optimizing equipment capability is essential for building and construction firms intending to make the most of functional Get More Information efficiency and minimize downtime. By prioritizing machinery functionality optimization, building and construction firms can enhance efficiency, prolong equipment life expectancy, and ultimately achieve greater returns on their heavy equipment financial investments.

In conclusion, utilizing costs aftermarket building components for hefty equipment offers numerous benefits, consisting of enhanced efficiency, cost-effective upgrades, enhanced durability, and maximized functionality.

Report this wiki page